Injection Molding

DITTER PLASTIC® uses multi-component injection-molding machines with rotary table transfer technology and clamp forces up to 1.500 tons for parts weighing up to 12000 grams. They are fully automatic and can work around the clock for high output, but their primary systems and peripherals are also designed for flexibility and quick modifications to meet ever-changing requirements.

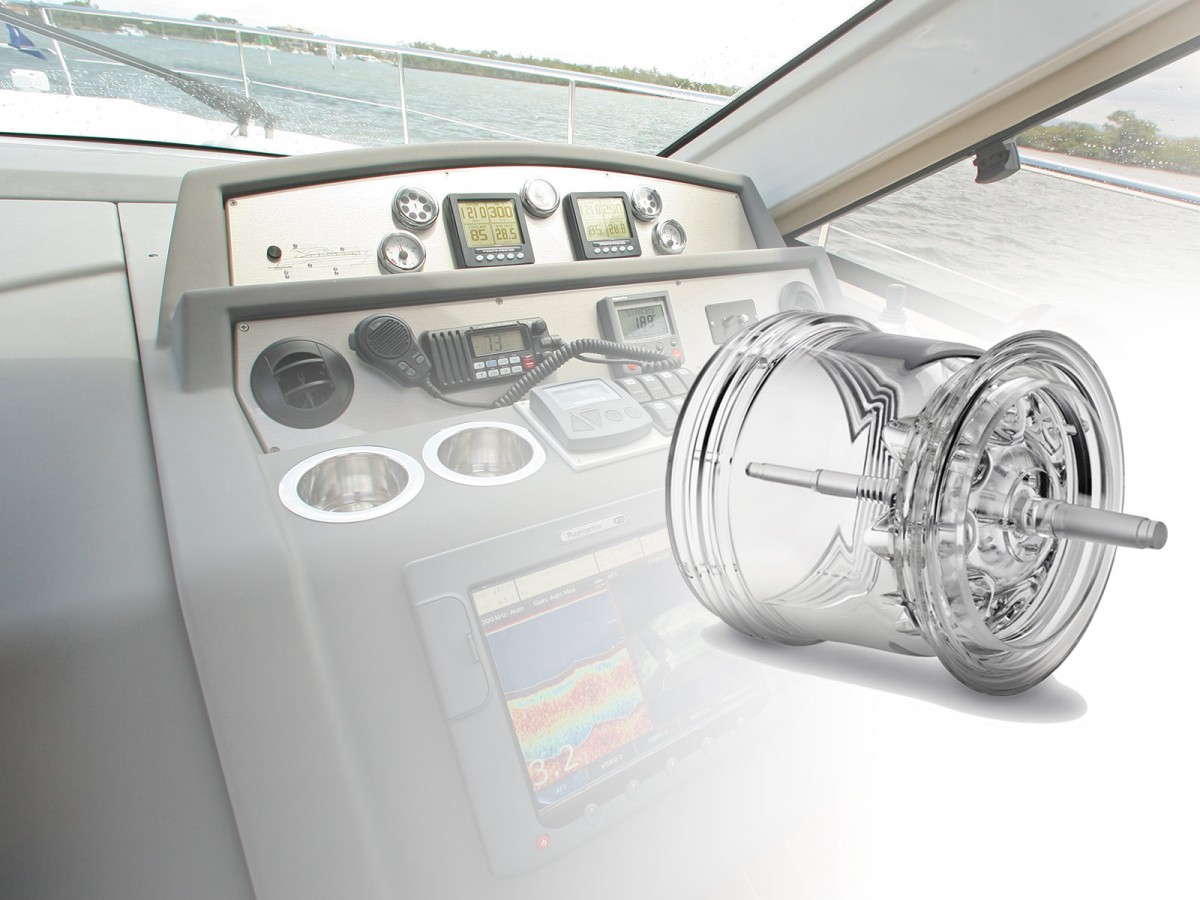

DITTER PLASTIC® uses the latest injection moulding technology, processing up to five components simultaneously with rotary tables, index tools and simultaneous injection moulding technology, expandable with transfer technology, in-mould decoration and plastic or metal inserts.