Paint / laser & printing

Depending on application and customer demand, DITTER PLASTIC® uses several processes for product refinement:

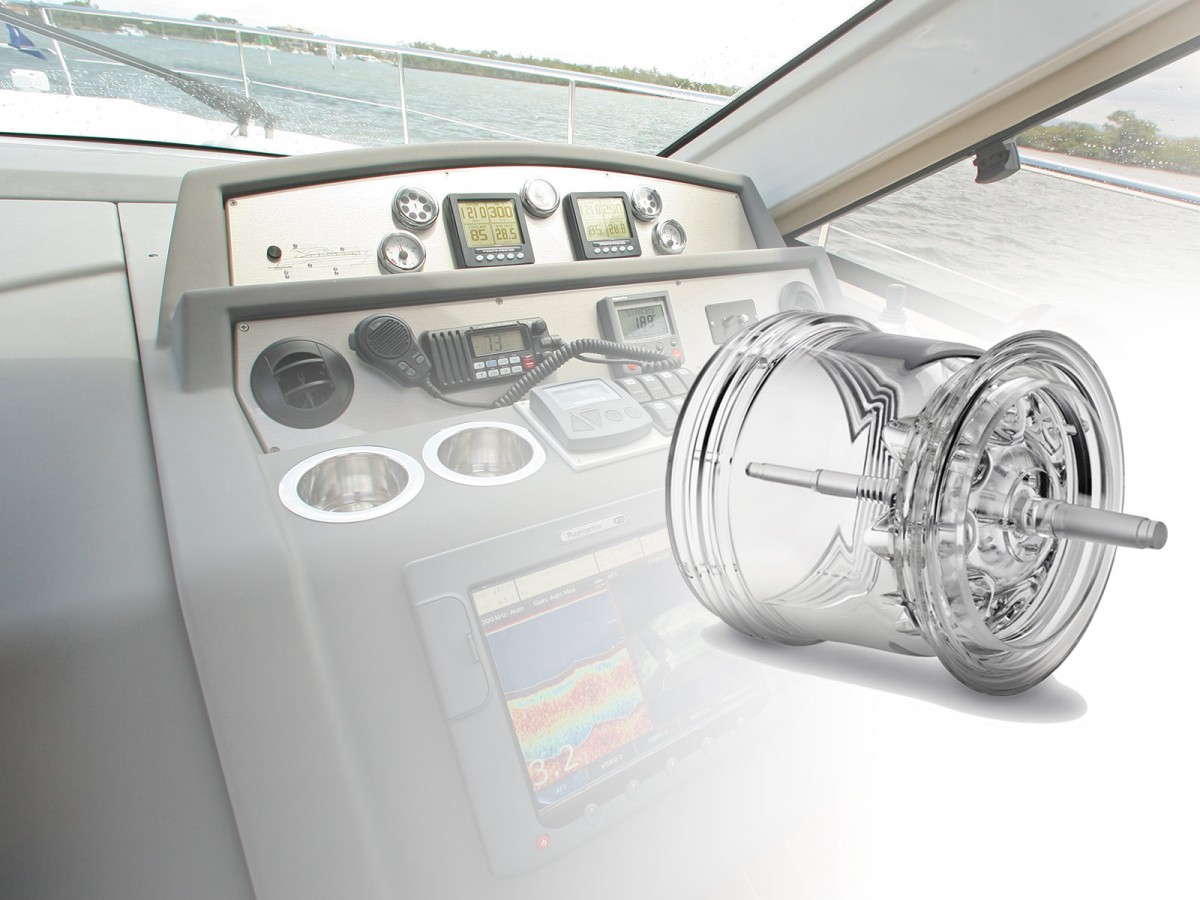

Laser etching, pad-, screen-, thermo- and multi-colour printing, film technology with back injection moulding, in-mould decoration, metallisation and PVD coating, friction-, ultrasonic-, hot plate- and laser beam welding, painting with pre-cleaning by CO2, ionised air or flame impingement; one- and two-component-, high-gloss-, UV- and water-based paint. With chromed parts, there is a choice between traditional galvanising and environmentally friendly, cost-effective chrome effect paint, a process that achieves the same gloss and appearance as galvanized parts.

Video file

Video file

Video file